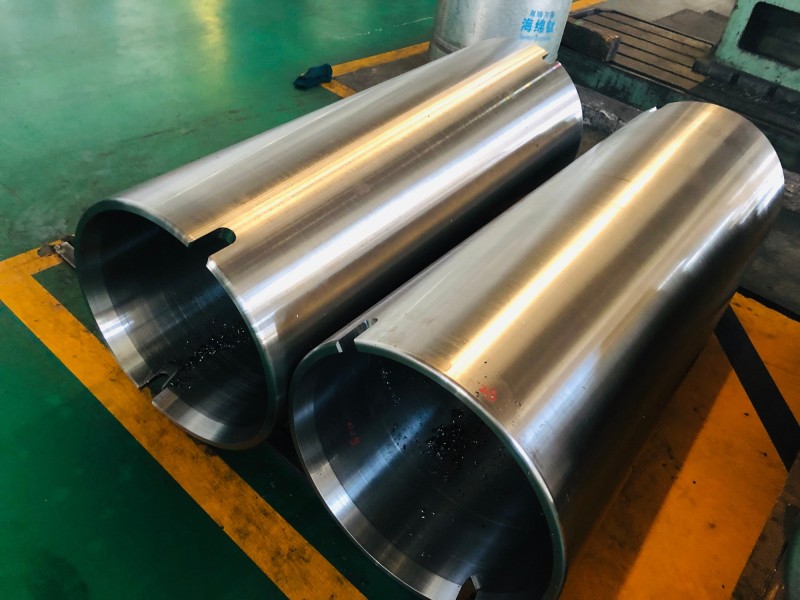

Carrete de acero fundido utilizado en la laminación de láminas de aluminio no ferrosas

Principales escenarios de aplicación de manguitos de acero fundido para laminadores de láminas de aluminio no ferrosos

Laminador de precisión de láminas de aluminio

Manguito del eje del núcleo del enrollador

Soporta tensión de bobinado de alta velocidad de lámina de aluminio (velocidad de línea ≥ 1200 m/min)

Pulido de espejo de superficie (Ra ≤ 0,1 μm) para evitar rayones en papel de aluminio

Laminador en frío de tiras de aluminio de alta precisión

Manguito de rodillo tensor

Control dinámico de la fluctuación de la tensión de la banda (dentro de ± 1%)

Diseño de ranura de aceite en espiral interna, adecuado para sistemas de microlubricación.

Molino de laminación de láminas especiales (como láminas de aluminio para baterías de litio)

Requiere interferencia magnética cero y tratamiento de desmagnetización (campo magnético residual ≤ 2 Gauss)

- GW Precision

- Luoyang, China

- Estipulación contractual

- La capacidad anual del carrete de acero es de 4000 piezas.

- información

Casting Steel Spool Used In Rolling Mill Machine Of Non-ferrous Aluminum Foil

Specifications | Material | |

colored aluminu strip mill steel sleeve | Φ 565 * 505 * 1700 mm | 35NiCrMo |

Materials and chemical composition of cast steel sleeves for non-ferrous aluminum foil rolling mills (GB/T 3077)

Element C Si Mn Ni Cr Mo P/S

Range 0.30-0.38 0.15-0.35 0.40-0.70 1.00-1.50 0.60-1.00 0.15-0.30 ≤ 0.020

Material characteristics:

Ni Cr Mo composite strengthening: improving low-temperature toughness (-40 ℃ AKv ≥ 35J)

Low S/P control: avoid hot rolling brittleness

Heat treatment specification for cast steel sleeves used in non-ferrous aluminum foil rolling mills

Process temperature (℃) Cooling method Target performance

Normalize 880-900 air cooling to refine grain size

Quenching 850 ± 10 polymer quenching core HRC32-36

Cryogenic treatment -196 ℃ × 2h liquid nitrogen residual austenite<3%

Tempered 560-580, water-cooled hardness HRC28-32

Mechanical processing standard for cast steel sleeves used in non-ferrous aluminum foil rolling mills

Parameter requirement detection method

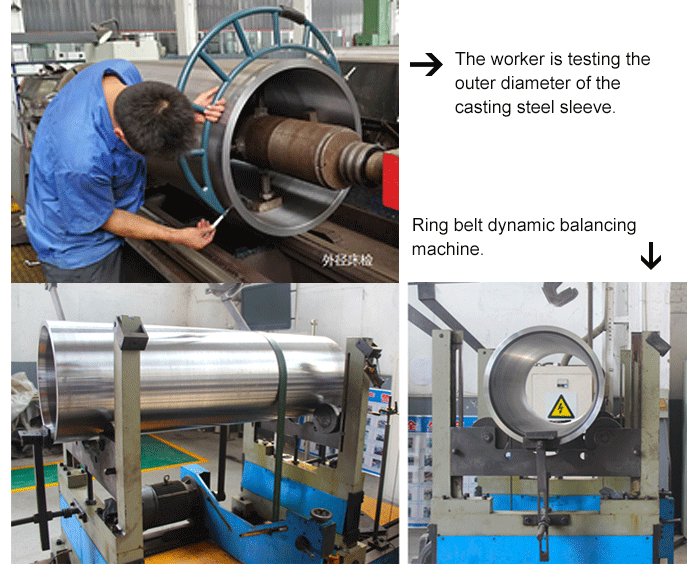

Inner hole accuracy of 200mm ± 0.005mm (IT5) three coordinate measuring instrument

Cylindricity ≤ 0.003mm/100mm roundness tester

Dynamic balance level G0.4 (ISO 1940) high-speed dynamic balance test bench

Surface roughness Ra ≤ 0.05 μ m (mirror) white light interferomete

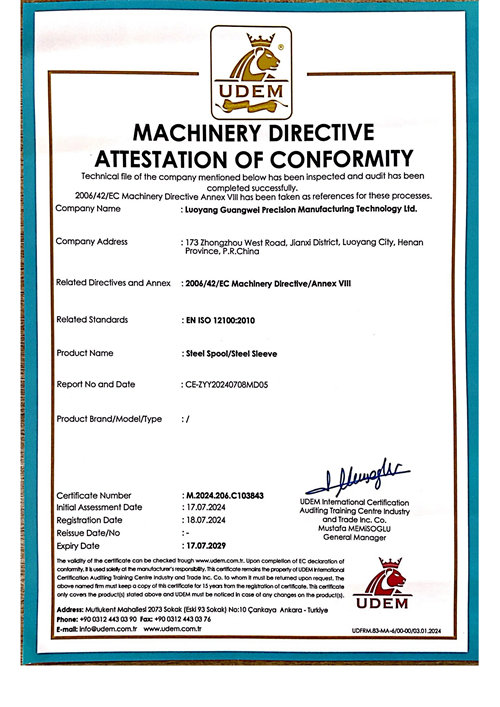

In terms of inspection,Strict inspection and testing procedures are our quality assurance. Each cast steel sleeve has a complete set of chemical composition analysis report, heat treatment report, material mechanical analysis report, dimensional tolerance, shape and position tolerance inspeaction report, all of which have traceability.

Packaging

We have excellent packaging team and mature packaging technology for each cast steel sleeve.

The packaging must ensure the safety of the products, so that they will not be lost or damaged during storage, transportation and sale.

Packing ensures product cleanliness. Confirm the cleanliness of product surface before packing.

Our cast steel sleeve products are widely recognized and trusted by users and can meet continuously changing economic and social needs.

Start your day off right by reaching out to Luoyang Guangwei Precision Manufacturing Technology Ltd. for any casting steel spool spindle repair needs you may have.

We have the technology,the eauipment and the knouledge to make sure that you will be 100% satisfied.

Our technicians are extremely experiences and are some of the best in the industry.

Come see how we can save you downtime and keep you up and running.

Time is money,make the call now!

guangwei@gwspool.com or +86-379-64593276

FAQ

1. Can You Make This Product According To The Customer's Requirement?

A: Yes, we can follow your specific requirements.

2. Can I Visit Your Factory Before We Ordering ?

A: Yes, welcome to our factory for field trip.

3. Where Is The Nearest Port To You Company?

A: Shanghai port is the nearest one.

4. Can We Choose Different Materials?

A: Yes, it can be selected depend on your requirements.

5. How Long Gone Take When You Finsh The Product And Deliver To Me?

A: It usually takes one and a half to two months by sea. It depends on the quantity of your order.

6. What Is Your Cover Of The Package?

A: We use wooden box to export.